Solar Desalination

Distillation means evaporation and condensation of a fluid. The resulting condensed product is free from salt. This basic principle, as natural as rain, is widely used in sea-water desalination.

Solar desalination is a technique to desalinate water using solar energy. Solar desalination in the modern era extends back to the early 1950s when simple solar stills were studied for remote desert and coastal communities. However, because of inexpensive water pumps and pipelines and declining energy costs in the 20th century, solar stills have become less of a viable solution for these community-scale projects.

Although everybody recognizes the strong potential of solar thermal energy to seawater desalination in arid and semi–arid regions due to the usual coincidence of water shortage, good solar radiation and seawater availability, the process is not yet developed at commercial level.

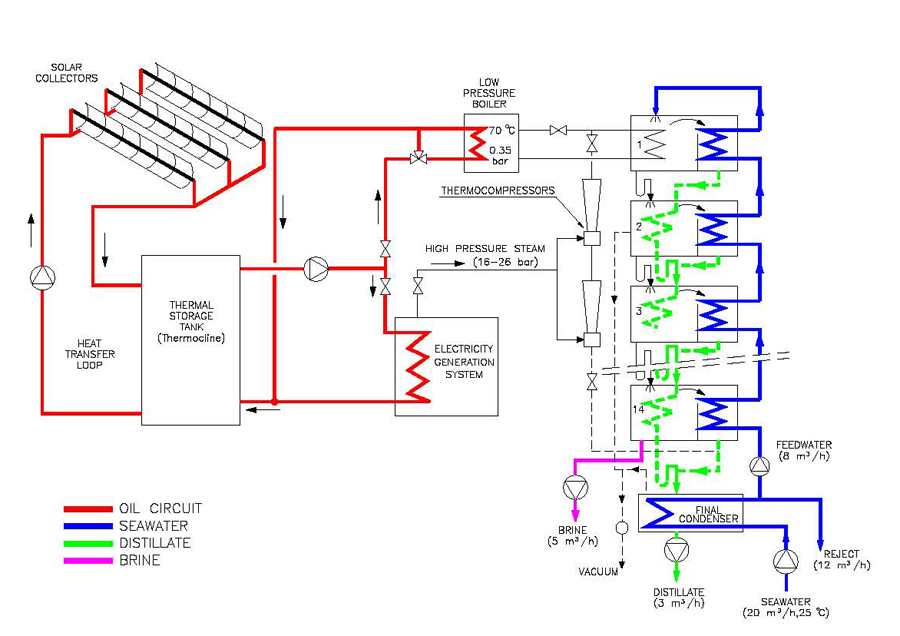

The two main sea water distillation processes are called Multi-Stage Flashing (MSF) or Multi-Effect Desalination (MED). Depending on the availability of energy on-site, and its quality, MED plants may be fitted with a compressor (thermal or mechanical) in order to enhance their performance and to optimise energy requirements. The processes are then called MED-TVC (Thermal Vapour Compression) and MED-MVC (Mechanical Vapour Compression).

During the 90s, the Plataforma Solar de Almer´ıa developed a unique experience in the desalination of seawater with solar energy. The developed technology, based on Multi-Effect Distillation systems coupled with parabolic trough collectors, although demonstrated as technically feasible, can not presently compete, on produced water cost basis, with conventional thermal distillation and reverse osmosis technology. However there is still important room for improvement of MED systems based on solar thermal energy. New concepts and ideas have been recently transformed into a new project, named AQUASOL, with the main objective of reducing the current cost of fresh water production from seawater. A first analysis shows that the new technology proposed will be fully competitive if the achieved associated total cost of the solar system is around 300 e/m2.

A shortage of fresh water is a very important problem that is continuously increasing, due to population growth and changes in weather conditions, and affects many countries in the world. These countries usually have abundant seawater resources and a good level of solar radiation, which could be used to produce drinking water from seawater. Although everybody recognizes the strong potential of solar thermal energy to seawater desalination, the process is not yet developed at commercial level. The main reason for this is that the existing technology, although already demonstrated as technically feasible, cannot presently compete, on produced water cost basis, with conventional thermal distillation and reverse osmosis technologies. Nevertheless, it is also recognized that there is still important room to improve desalination systems based on solar thermal energy.

Click on the photo to view full Design

Among low capacity production systems, solar ponds represent the best alternative in case of both low fresh water demand and land price. For higher desalting capacities, it is necessary to choose conventional distillation plants coupled to a solar thermal system, which is known as indirect solar desalination (Garc´ıa–Rodr´ıguez and G´omez–Camacho, 2001). Distillation methods used in indirect solar desalination plants are multi–stage flash (MSF) and multi–effect distillation (MED). MSF plants, due to factors such as cost and apparent high efficiency, pushed out MED systems in the sixties, and only small size MED plants were built. However, in the last decade, interest in multi–effect distillation has been significantly renewed and currently MED process is competing technically and economically with MSF technology (Al-Shammiri and Safar, 1999; Alawadhi, 2002). Recent advances in research of low temperature processes have resulted in an increase of the desalting capacity and a reduction in the energy consumption of MED plants (Kronenberg and Lokiec, 2001), providing long-term operation under remarkable steady conditions. Scale formation and corrosion are minimal, leading to exceptionally high plant availabilities of 94% to 96%.

|